Operating the 1522 on the road was both a joy and an awful lot of stress. Nobody felt this more than the three gentlemen who were 1522's engineers during her excursion days. Jeff Schmid was the only one of the three who was a railroader by occupation. He hired on as an engineer on the Frisco and transitioned to the Burlington Northern (BN) and eventually what is now the Burlington Northern Santa Fe (BNSF). Don Wirth was a machinist by trade but also the son of a Frisco engineer. He grew up around the railroad in St. Louis with his dad and is a walking encyclopedia of Frisco information as well as an expert model railroader. Don was the Chief Mechanical Officer of the SLSTA. Wellie Lazier was a probation officer with no direct link to the Frisco apart from an interest in steam trains. He was also the Vice President of the SLSTA. These men had to learn how to operate the 1522 and Don/Wellie also took engineer training from the BN/BNSF to qualify as engineers to operate the train safely. Not only were the lives of hundreds of fans on the train in their hands - they had to contend with lots of people trackside to see the train, too. They were also running a restored, cantankerous old steam engine - not a reliable modern diesel. Doyle McCormack, the engineer of the restored Southern Pacific 4449, told us early on that the steam engine will always figure out a way to bite you when you least expect it. So true, as we came to learn.

As the SLSTA matured, the operating crew grew used to the 1522 and her operational quirks - all locomotives have them. Wherever we went, we took along a local engine crew who knew the territory and could advise our engineers on upcoming grades, curves, slow orders, etc. Most of the time these crewmen were very helpful and accommodating. Wherever possible, our engineer would slip out of the seat and let the local engineer have a chance to run the throttle for a few minutes. We also would often have a road foreman or other senior railroader and often they were given a chance at the throttle. Most of these people were qualified to operate modern trains but had little or no experience operating a steam locomotive. Our engineer would be next to them advising them what to do so as not to abuse the 1522 and most of them would listen and comply. However, not all did and it could be very stressful to watch someone who thinks they know it all operating the 1522 incorrectly.

One of the major problems for independent groups like ours operating steam locomotives in the modern day is that all the track in this country is privately owned. Some railroads, like the Chicago and North Western (C&NW - now part of the Union Pacific), BN/BNSF, Norfolk Southern and others were accommodating to 1522 operations. Some railroads, such as CSX, are not interested in operating steam. The Union Pacific has its own excellent steam program and doesn't need anyone else's steam engine on their tracks - although, to be fair, they were very helpful to us getting the 1522 to and from its home at the Museum of Transport.

On some of the trips we took, the host railroad mandated that one of their own engineers operate the 1522 and train. A SLSTA crewmen would still be firing the engine and one of our engineers would be there to advise on 1522's operational quirks, but the only one at the throttle was a host railroad engineer. These engineers had experience operating steam locomotives but not our locomotive. Sometimes they did things to the 1522 which might be normal for their other engines but not ours. Sometimes they just didn't care. Attempts to educate them on our engine or request they do things differently often fell on deaf ears. That did not sit well at all but if we wanted to run on their railroad we were stuck with this setup.

One incident which still gives all 3 of our engineers nightmares involved a service stop. A host railroad Road Foreman had been operating the 1522 and not too kindly at that. When he spotted the train for its service stop, the Foreman got off and disappeared into the station. Our service crew set to work greasing and servicing the locomotive which, for the soft grease crew especially, involved having their hands in among the various rods and arms which make up the reversing gear. Both Don and Jeff remember something seeming amiss. Jeff noted a serious amount of backpressure showing on the gauge and Don said something didn't sound right. The Road Foreman had left the throttle cracked open and pressure was building inside the cylinder. Apparently the snifter valves (see below) had enough steam pressure still applied that they never got the chance to open up and relieve all pressure in the pipes. The service crew was immediately ordered away from the engine, the throttle was closed and the cylinder cocks were opened to relieve the pressure. Had the 1522 actually moved, the service crew and others could have been seriously hurt.

Operating a steam locomotive is a two person effort. The fireman needs to anticipate the steam that will be needed and make enough of it available - but not so much that it is venting away and wasting fuel and water. The engineer is operating the train but as part of this his throttle settings determine the amount of draft the fireman's fire will receive. The engineer needs to keep in mind at all times what the fireman is trying to accomplish. When we ran the 1522 with our own engineer and fireman, the same people often worked together and developed a good cooperative routine to keep the engine going. Guest engineers were not used to working together with our fireman and would sometimes operate the throttle such that the fire had little or no draft. Add in the occasional load of bad fuel oil or hard water and life could be miserable at times. Again, though - it's their railroad so we either play by their rules or we don't get to use it.

Several incidents during the operation of the 1522 involved the left or right hand snifter valves. Don Wirth describes the snifter valve function and operation:

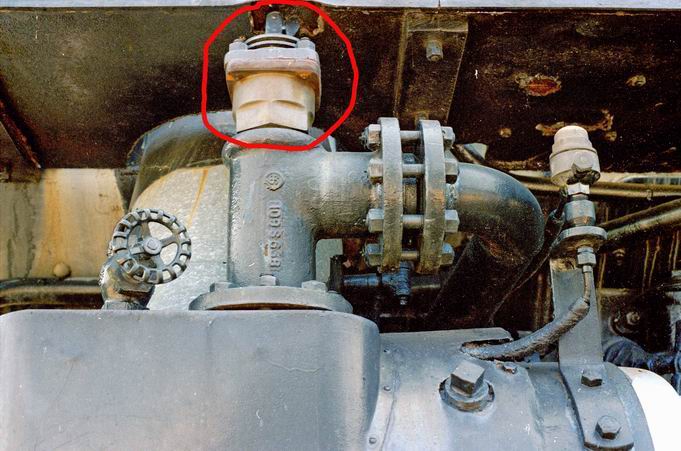

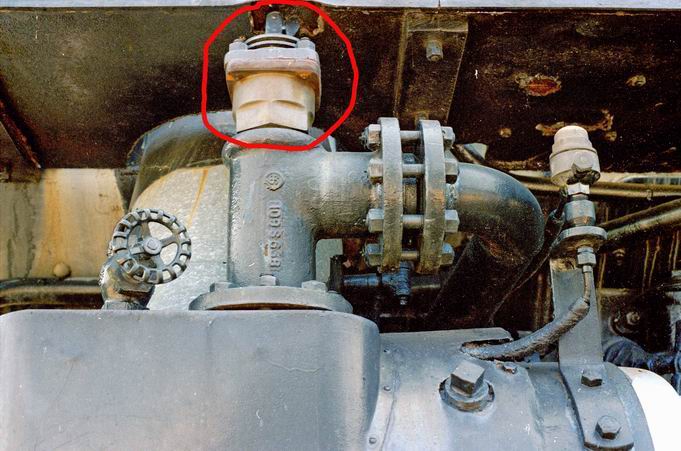

In the photo above showing the top of the 1522's cylinder, the snifter valve is circled. It is like a valve in an automobile engine and the head is facing down inside. It is normally open with the throttle closed and when the throttle is opened, the steam pressure closes it. You can hear the PSST when you open the throttle until the snifter valve closes. The snifter serves several functions - if the engine is parked and the throttle is leaking, it will vent the steam safely out and prevent pressure buildup in the cylinders. If you are running and close the throttle tight, the valve opens and breaks the vacuum caused by the piston moving in the cylinder. This also prevents crud from the exhaust from being sucked backwards into the cylinder.

The snifter valve has a semi-circular flipper on top which can be used to manually hold the valve open. When the locomotive is in the roundhouse or stationary for a long time, the crew can flip the flipper over and it holds the snifter valve open. Usually the cylinder cocks and house valves were opened during prolonged rests for additional protection against steam building up. During normal running, the snifter valve would open or close on its own as needed. However, if the engineer slammed the throttle closed while running, sometimes it would cause the flipper to swing around and hold the snifter valve open. This would create a hole in your steam pipe and reduce steam pressure in that cylinder. This happened several times with guest engineers operating the 1522 and not following the guidance of our engineers. In one case, the host railroad engineer turned the throttle back over to our engineer, climbed out on the running board at 40mph and flipped the flipper back over to close the valve. Wellie noted another occasion where he was working 1522 up a slight grade and, after passing through a rail oiler, the drivers started slipping. He immediately shut the throttle which caused the snifter valve flipper to flip. He stopped the train, went up to the valve and flipped the flipper back. No big deal but the unscheduled stop caused some remarks from a host railroad official on board which did not sit well with the crew.

Most of the 1522 trips were in the heat and humidity of mid-summer. This had the whole crew sweating but sometimes for different reasons. Jeff Schmid relates the following regarding the 1990 NRHS Convention trip from St. Louis to Newburg and back, 1522's first time on her old home rails:

"I remember on the 1990 NRHS Convention trip, I ran out of Chouteau Yard. Sweated bullets wondering if I could start the train on that hill, but did so thanks to the booster. We stopped briefly at Pacific and Wellie got in the seat and I stayed in the cab. Going up Dillon Hill, Fireman Don Morice couldn't get the left injector to pick up. Tried the engineer side injector; no luck. No water in the sight glass. Wellie went down the three tricocks* and verified no water. Talk about sweating profusely in addition to the already horrible heat. Wellie was out of the seat talking to Morice and I took over running. We discussed dropping the fire, in addition to other responses while waiting for the boiler explosion. I backed off the throttle a little and finally got to the top of the hill and started down into Rolla. Going downhill we finally got some water. Going through Rolla I kept the speed down watching for hydrants. Saw one just east of where the 1501 is on display. I big-holed it to try and stop quickly without having to back up. Got the word out to the crew and they immediately started the watering process. Our Road Foreman came running up and thought we had hit a car.

"When we got started again I noticed steam blowing above the right valve. I had no idea the sudden stop and throttle shut off had flipped the snifter valve flipper. I don't think Wellie or Don Morice realized it either. So all the way down into Newburg we're sweating even more, wondering what flaw the engine has suffered now. At Newburg we told Don Wirth about it, and he didn't say anything - just walked up and flipped the valve flipper back off. What a relief. I was totally whipped and after a few minutes I walked over to Blue's Market and stood inside in the air conditioning for a while during the servicing. After turning on the wye at Bundy Junction (just West of Newburg), Don took the train up Rolla Hill. Out of paranoia we did another water stop at Rolla, although we probably would have had enough water to make it back.

"Later Ted Cover (our water treatment expert on the crew) told me that he did water sampling and treatment that morning before we left Chouteau Yard and he noticed the tender was down, maybe several thousand gallons? Wonder if our night fireman left an injector valve open during the night while firing? Also, we decided that going uphill, water in the tender was flowing back into the auxiliary, partially explaining why we ran low going up Dillon Hill.

Wellie Lazier related the following incident on our 1995 Heartland Tour through Iowa. We had departed Lincoln, Nebraska, heading out of the Missouri River valley up toward Red Oak, Iowa:

"After cresting a hill, I started to reduce the throttle. There was this strange moment before I realized the engine wasn't responding to the throttle. Then it sunk in, regardless of where the throttle was, we were accelerating! I set the brakes, put the reverser on center, and opened cylinder cocks. As the train began to slow, I continued to try to get the throttle to respond by moving it rapidly back and forth, and leaning on it. The pilot engineer and I tried together to push it closed. No luck! All I could think of was the steam pipe had ruptured. As the train continued to slow, miraculously throttle response returned. Later in the evening on the Red Oak siding we uncoupled the engine and ran it back and forth trying to recreate the issue to no avail. Speculation at the time was that a piece of scale had somehow jammed the throttle open. It would not take much - at full opening, the throttle valve only opens 1/2 inch. Later inspection at the NMOT suggested that it more probably was an issue associated the throttle rod and valve mechanism. Luckily the issue never occurred again."

Don Wirth was running the engine on a trip through Oklahoma and related the following:

"I found out the hard way that somebody closed the water valve on the tender on my side. For some reason Willie (Fireman Willie Webster) was falling behind on water and I put my injector on and blew the water hose off. Called somebody up from the tool car with a wrench and dropped the fire. Ten minutes later all was well except for the upholstery on the seatbox."

Operating in 90 degree heat and humidity was one thing if you were on the train or trackside but quite another if you were in the cab. With the firebox sharing the space, the temperature was often 20-30 degrees hotter than outside. If the engine was moving, usually there was enough airflow through the cab to keep the crew fairly comfortable but otherwise it was like working in a sauna. Going back to the crew cars to cool off wasn't much of a change since neither of them had any air conditioning, either. This was why it was always good to have the lounge car Chouteau Club along - it did have air conditioning and the crew could sit in there and cool off. All three of our engineers talked of being seriously overcome with heat at one or more times during operations.

Jeff Schmid put it well, saying, "Running 1522 was incredibly fulfilling, but inevitably there was always STRESS. I'm sweating just typing these memories." Wellie Lazier added, "After each trip as we pulled back into the NMOT, I always felt a great sense of relief that we made home. After successful trips I also enjoyed a feeling of accomplishment. There was nothing sweeter than rolling down the railroad at 60mph, everything set right, listening to the engine and enjoying the ride."